Case Study: Water Audit Success in Manufacturing Plant

Discover insights on water treatment solutions and technologies.

In this comprehensive case study, we examine how ChemParks conducted a successful water audit at a large automotive manufacturing facility, resulting in 40% water consumption reduction and annual savings of $850,000.

Client Background

A major automotive manufacturing plant with 1.2 million square feet of production space faced increasing water costs and regulatory pressure to reduce consumption. The facility used approximately 120 million gallons of water annually across multiple processes including cooling towers, plating operations, paint booths, and general manufacturing.

Audit Objectives

The comprehensive water audit aimed to:

- Identify all water consumption points and quantify usage

- Locate hidden leaks and inefficient processes

- Evaluate water quality requirements for each application

- Identify water reuse and recycling opportunities

- Develop cost-effective implementation strategies

Audit Methodology

ChemParks employed a systematic approach to conduct the water audit:

Phase 1: Data Collection and Analysis

The initial phase focused on gathering comprehensive water usage data:

- Utility Bill Analysis: Reviewed 24 months of water and sewer bills to establish baseline consumption patterns

- Process Mapping: Identified and documented all water-using processes and equipment

- Flow Meter Installation: Temporarily installed meters on major water circuits to validate usage data

- Water Quality Testing: Analyzed water quality at various points to assess reuse potential

Phase 2: On-site Assessment

Detailed field investigations revealed critical issues:

- Leak Detection: Ultrasonic testing identified 38 hidden leaks totaling 12.4 gallons per minute

- Equipment Inspection: Assessed condition and efficiency of water-using equipment

- Operational Practices: Observed and evaluated water usage procedures and practices

- Meter Calibration: Verified accuracy of existing water meters and flow meters

Phase 3: Water Balance Development

Created a comprehensive water balance for the facility:

- Cooling Tower System: 45% (54 million gallons/year)

- Plating Operations: 25% (30 million gallons/year)

- Paint Booth Operations: 15% (18 million gallons/year)

- General Manufacturing: 10% (12 million gallons/year)

- Sanitary and Miscellaneous: 5% (6 million gallons/year)

Key Findings

The audit revealed several significant opportunities for water conservation:

Critical Issues Identified

- Hidden Leaks: 38 undetected leaks wasting 6.5 million gallons annually

- Inefficient Cooling Towers: Operating at 3.5 cycles of concentration instead of optimal 6.0

- Single-pass Cooling: Several processes using water only once before discharge

- Overflows and Runoff: Poor process control causing unnecessary water waste

- Lack of Recycling: No water reuse systems despite suitable applications

Water Quality Mismatch

Significant quality mismatches were found between water supply and process requirements:

- Potable water used for non-critical cooling applications

- Overly purified water used for rinsing operations

- RO reject water discharged despite suitable reuse potential

Recommended Solutions

ChemParks developed a comprehensive implementation plan with prioritized recommendations:

Immediate Actions (0-3 months)

- Repair Program: Fix all identified leaks - estimated savings: 6.5 million gallons/year

- Cooling Tower Optimization: Increase cycles to 6.0 with proper treatment - savings: 15 million gallons/year

- Process Control Improvements: Eliminate overflows and unnecessary flows - savings: 8 million gallons/year

- Staff Training: Implement water conservation training programs

Short-term Projects (3-12 months)

- Rinse Water Recycling: Implement counter-current rinsing in plating operations - savings: 10 million gallons/year

- Cooling Water Reuse: Use cooling tower blowdown for non-critical applications - savings: 5 million gallons/year

- High-efficiency Fixtures: Install water-efficient equipment in sanitary facilities

- Automated Monitoring: Install real-time water usage monitoring system

Long-term Investments (1-3 years)

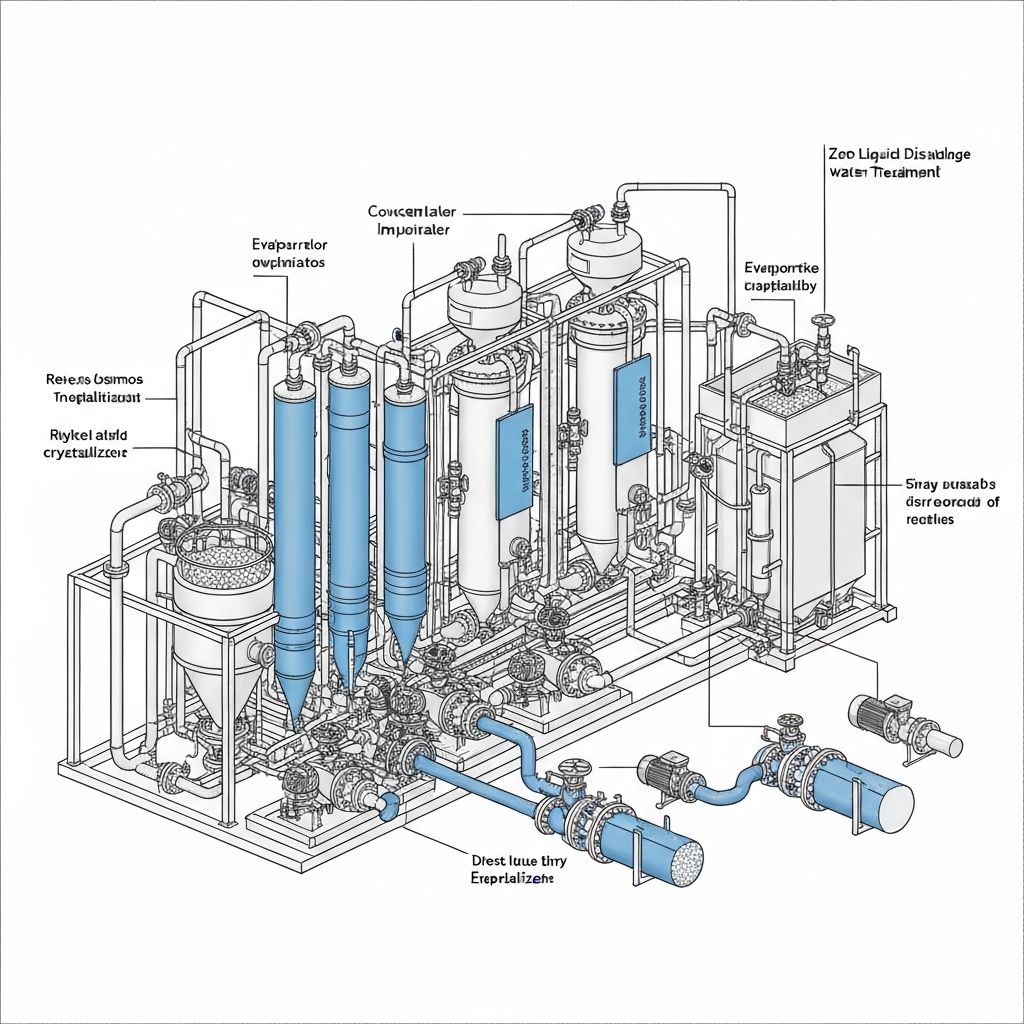

- Comprehensive Recycling System: Full-scale water treatment and reuse plant - savings: 15 million gallons/year

- Closed-loop Cooling Systems: Convert single-pass systems to recirculating designs

- Advanced Process Controls: Implement AI-driven water optimization systems

Implementation Results

The facility implemented recommendations in phases, achieving remarkable results:

Year 1 Achievements

- Water Consumption: Reduced from 120 to 85 million gallons (29% reduction)

- Cost Savings: $485,000 in water and sewer costs

- Leak Elimination: All 38 leaks repaired within 60 days

- Cooling Tower Efficiency: Increased cycles to 5.8 with stable operation

Year 2 Achievements

- Total Water Reduction: Achieved 40% reduction (72 million gallons annually)

- Annual Savings: $850,000 in water, sewer, and energy costs

- ROI: 165% return on investment within 24 months

- Environmental Impact: Reduced wastewater discharge by 48 million gallons

Technical Implementation Details

Cooling Tower Optimization

The cooling tower optimization project involved:

- Installation of automated conductivity controllers

- Implementation of advanced corrosion inhibitors

- Upgrade of drift eliminators to reduce water loss

- Installation of real-time monitoring sensors

Rinse Water Recycling System

The plating operation recycling system included:

- Counter-current rinse system design

- Ultrafiltration pretreatment for water polishing

- RO system for final purification

- Automated quality monitoring and control

Financial Analysis

Investment Breakdown

- Phase 1 (Immediate Actions): $85,000

- Phase 2 (Short-term Projects): $320,000

- Phase 3 (Long-term Projects): $510,000

- Total Investment: $915,000

Return on Investment

- Annual Savings: $850,000

- Payback Period: 14 months

- 5-Year ROI: 365%

- 10-Year ROI: 828%

Lessons Learned

Key Success Factors

- Management Commitment: Executive support was crucial for implementation

- Employee Engagement: Staff training and involvement ensured program success

- Phased Implementation: Staggered approach allowed manageable execution

- Continuous Monitoring: Real-time data enabled ongoing optimization

Implementation Challenges

- Initial resistance to operational changes

- Coordination with production schedules

- Budget constraints for capital projects

- Technical expertise requirements

Ongoing Improvements

The facility continues to optimize water usage through:

- Monthly water audits and performance reviews

- Annual water conservation training programs

- Continuous improvement initiatives

- Technology upgrades and process optimization

Conclusion

This case study demonstrates the significant impact that comprehensive water audits can have on industrial operations. Through systematic assessment and strategic implementation, the facility achieved substantial water conservation, cost savings, and environmental benefits.

The success of this project highlights the importance of professional water audit services in identifying hidden opportunities and developing effective conservation strategies. ChemParks continues to work with the facility to identify further optimization opportunities and maintain leadership in water stewardship.

Contact ChemParks to schedule a comprehensive water audit for your facility and discover similar opportunities for conservation and cost savings.