Zero Liquid Discharge: Sustainable Solutions for Industries

Learn how ZLD systems help industries achieve environmental compliance while reducing water consumption and waste through advanced membrane technologies.

The Growing Importance of Zero Liquid Discharge Systems

Industries worldwide are facing increasing pressure to adopt sustainable water management practices. Zero Liquid Discharge (ZLD) systems have emerged as a comprehensive solution that not only addresses environmental concerns but also offers significant economic benefits.

What is Zero Liquid Discharge?

ZLD is an advanced wastewater treatment process that eliminates liquid waste discharge. By employing a combination of advanced treatment technologies, ZLD systems convert wastewater into clean water for reuse and solid waste for disposal or resource recovery.

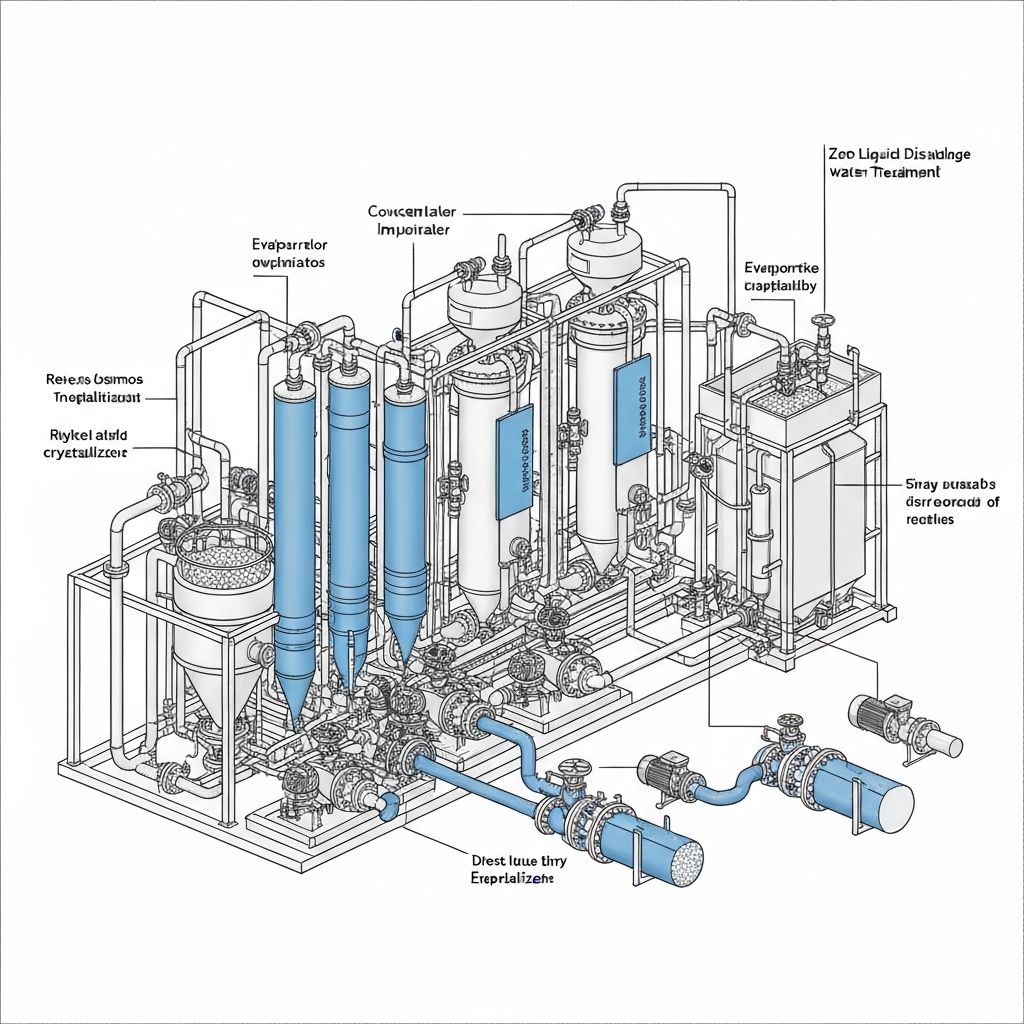

Key Components of ZLD Systems

1. Pre-treatment Systems

Effective ZLD begins with proper pre-treatment:

- Screening and filtration to remove suspended solids

- pH adjustment for optimal downstream processing

- Softening to prevent membrane scaling

- Organic matter removal through biological treatment

2. Advanced Membrane Technologies

Membrane systems form the backbone of ZLD:

- Ultrafiltration (UF): Removes fine suspended particles and colloids

- Nanofiltration (NF): Targets divalent ions and organic compounds

- Reverse Osmosis (RO): Produces high-quality permeate water

- Electrodialysis (ED): Efficiently separates charged species

3. Evaporation and Crystallization

For maximum water recovery:

- Multiple Effect Evaporators (MEE) for energy-efficient concentration

- Mechanical Vapor Recompression (MVR) for energy optimization

- Forced Circulation Crystallizers for salt recovery

- Spray Dryers for final waste solidification

Industry Applications

Textile Industry

Textile manufacturing generates highly colored, saline wastewater. ZLD implementation provides:

- Water recovery rates exceeding 95%

- Dye and chemical recovery opportunities

- Compliance with strict discharge regulations

- Reduced freshwater consumption

Petrochemical Industry

Complex petrochemical effluents require sophisticated treatment:

- Removal of hydrocarbons and dissolved solids

- Heavy metal concentration and recovery

- Reuse of treated water in cooling systems

- Minimization of hazardous waste generation

Pharmaceutical Sector

Pharmaceutical wastewater presents unique challenges:

- Removal of active pharmaceutical ingredients

- Recovery of valuable solvents and byproducts

- Meeting stringent regulatory requirements

- Water quality suitable for clean-in-place systems

Economic Benefits of ZLD

Direct Cost Savings

- Reduced Water Costs: Up to 90% reduction in freshwater purchases

- Lower Discharge Fees: Elimination of effluent discharge charges

- Resource Recovery: Revenue from recovered salts and chemicals

- Energy Recovery: Heat recovery from concentration processes

Indirect Benefits

- Enhanced corporate sustainability profile

- Improved regulatory compliance

- Better community relations

- Increased operational reliability

Challenges and Solutions

High Energy Consumption

Solution: Integration of energy recovery systems and renewable energy sources.

Capital Investment

Solution: Phased implementation and government subsidy programs.

Operational Complexity

Solution: Advanced automation systems and skilled operator training.

Future Trends in ZLD Technology

AI-Powered Optimization

Machine learning algorithms are being integrated to:

- Predict fouling and schedule maintenance

- Optimize energy consumption based on real-time conditions

- Automate chemical dosing for maximum efficiency

Hybrid Systems

Combining multiple technologies:

- Forward osmosis for low-energy concentration

- Membrane distillation for high-salinity streams

- Critical minerals recovery from concentrated streams

Regulatory Landscape

Governments worldwide are implementing stricter regulations:

- EPA's Effluent Limitation Guidelines becoming more stringent

- EU's Water Framework Directive mandating ZLD for specific industries

- India's CPCB promoting ZLD in industrial clusters

- China's Water Pollution Control Law requiring zero discharge

Conclusion

Zero Liquid Discharge systems represent the pinnacle of sustainable wastewater treatment. While challenges remain, technological advances and economic incentives are making ZLD increasingly viable for industries across sectors.

As water scarcity intensifies and environmental regulations become more stringent, ZLD will transition from being an option to a necessity. Industries that embrace this technology today will be better positioned to thrive in the water-constrained world of tomorrow.