Effluent Treatment Plant (ETP) Chemicals: Complete Guide

Discover insights on water treatment solutions and technologies.

Effluent Treatment Plants (ETPs) are essential for industrial wastewater management, utilizing a combination of physical, biological, and chemical processes to treat wastewater before discharge. This comprehensive guide covers the essential chemicals used in ETPs and their applications in achieving environmental compliance.

Understanding ETP Treatment Stages

Primary Treatment (Physical)

Initial removal of large solids and floating materials:

- Screening and grit removal

- Sedimentation in primary clarifiers

- Oil and grease separation

- pH adjustment and neutralization

Secondary Treatment (Biological)

Biological degradation of organic matter:

- Aerobic treatment (activated sludge)

- Anaerobic digestion

- Biological nutrient removal

- Biofilm reactors

Tertiary Treatment (Chemical/Advanced)

Polishing and advanced treatment processes:

- Chemical precipitation

- Advanced oxidation

- Membrane filtration

- Disinfection

pH Adjustment Chemicals

Acids for pH Reduction

Sulfuric Acid (H₂SO₄)

- Strong acid for rapid pH adjustment

- Cost-effective for large-scale applications

- Requires careful handling and storage

- Commonly used in industrial ETPs

Hydrochloric Acid (HCl)

- Strong acid with minimal scaling potential

- Effective for neutralizing alkaline wastes

- Produces soluble chlorides

- Used in food processing ETPs

Alkalis for pH Increase

Sodium Hydroxide (NaOH)

- Strong base for rapid neutralization

- Highly soluble and easy to handle

- Produces sodium salts in treated water

- Most commonly used alkaline chemical

Lime (Calcium Hydroxide)

- Cost-effective alkaline agent

- Also aids in precipitation of metals

- Produces insoluble calcium salts

- Requires sludge handling considerations

Coagulation and Flocculation Chemicals

Primary Coagulants

Aluminum Sulfate (Alum)

- Most widely used coagulant

- Effective pH range: 5.5-7.5

- Forms aluminum hydroxide flocs

- Good for turbidity removal

Ferric Chloride (FeCl₃)

- Effective over wider pH range

- Good for color removal

- Forms dense, settleable flocs

- Also provides some disinfection

Ferrous Sulfate (FeSO₄)

- Economical coagulant option

- Effective in alkaline conditions

- Requires oxidation to ferric form

- Commonly used in textile ETPs

Polyaluminum Chloride (PAC)

- Pre-polymerized coagulant

- Effective at lower doses

- Produces less sludge

- Wide pH operating range

Flocculants

Polyacrylamide Polymers

- Anionic, cationic, and non-ionic types

- High molecular weight polymers

- Bridge particles for larger flocs

- Dosage: 0.1-5 mg/L typical

Natural Flocculants

- Chitosan from shellfish waste

- Moringa oleifera seeds

- Starch-based flocculants

- Environmentally friendly options

Precipitation Chemicals

Heavy Metal Removal

Sodium Hydroxide

- Precipitates metals as hydroxides

- Common for chromium, nickel, zinc

- pH-dependent precipitation

- Produces metal hydroxide sludge

Sodium Sulfide

- Precipitates heavy metals as sulfides

- More effective than hydroxides

- Toxic and requires careful handling

- Generates H₂S gas in acidic conditions

Dimethyl Dithiocarbamate (DMDTC)

- Organic precipitant for heavy metals

- Effective at low concentrations

- Selective precipitation possible

- Expensive but highly effective

Phosphorus Removal Chemicals

Chemical Precipitation

Aluminum and Iron Salts

- Alum, ferric chloride, ferrous sulfate

- Form aluminum/iron phosphate precipitates

- Simultaneous coagulation and phosphorus removal

- Dose: 10-50 mg/L as Al/Fe

Lime

- Precipitates phosphorus as calcium phosphate

- High pH requirements (pH >9)

- Cost-effective for large applications

- Produces large amounts of sludge

Disinfection Chemicals

Chlorine-Based Disinfectants

Sodium Hypochlorite

- Liquid bleach (10-15% available chlorine)

- Easy to dose and handle

- Provides residual protection

- Forms disinfection byproducts

Calcium Hypochlorite

- Solid form (65-70% available chlorine)

- Longer shelf life than sodium hypochlorite

- Increases water hardness

- Requires dissolution before dosing

Advanced Oxidation

Hydrogen Peroxide

- Strong oxidizing agent

- No residual effect

- Breaks down to water and oxygen

- Often used with UV activation

Ozone

- Generated on-site from oxygen

- Most powerful oxidant

- No chemical residues

- High capital and operating costs

Sludge Conditioning Chemicals

Sludge Dewatering Aids

Cationic Polymers

- Improve sludge dewatering

- Reduce sludge volume

- Enhance cake solids content

- Optimize filter press operation

Lime

- Conditions sludge for dewatering

- Stabilizes organic sludge

- Reduces odor problems

- Improves sludge handling

Neutralization Chemicals

Acid Neutralization

- Sodium carbonate (soda ash)

- Calcium carbonate (limestone)

- Sodium bicarbonate

- Magnesium hydroxide

Base Neutralization

- Sulfuric acid

- Hydrochloric acid

- Carbon dioxide (for mild alkalinity)

Dosing and Control Systems

Dosing Equipment

- Metering pumps for liquid chemicals

- Dry feeders for powders and granules

- Automatic dosing systems

- Batch dosing equipment

Control Strategies

- Feedback control based on effluent quality

- Feed-forward control based on influent

- Ratio control for proportional dosing

- Adaptive control for optimization

Safety and Environmental Considerations

Chemical Handling

- Material Safety Data Sheets (MSDS)

- Personal protective equipment

- Spill containment measures

- Emergency response procedures

Environmental Impact

- Biodegradable chemical options

- Minimization of chemical usage

- Proper sludge disposal

- Regulatory compliance

Industry-Specific Applications

Textile Industry

- Color removal chemicals

- High BOD/COD reduction

- Dye fixation chemicals

Pharmaceutical Industry

- API removal chemicals

- Solvent recovery

- Advanced oxidation requirements

Food Processing

- Organic load reduction

- Oil and grease removal

- Nutrient removal

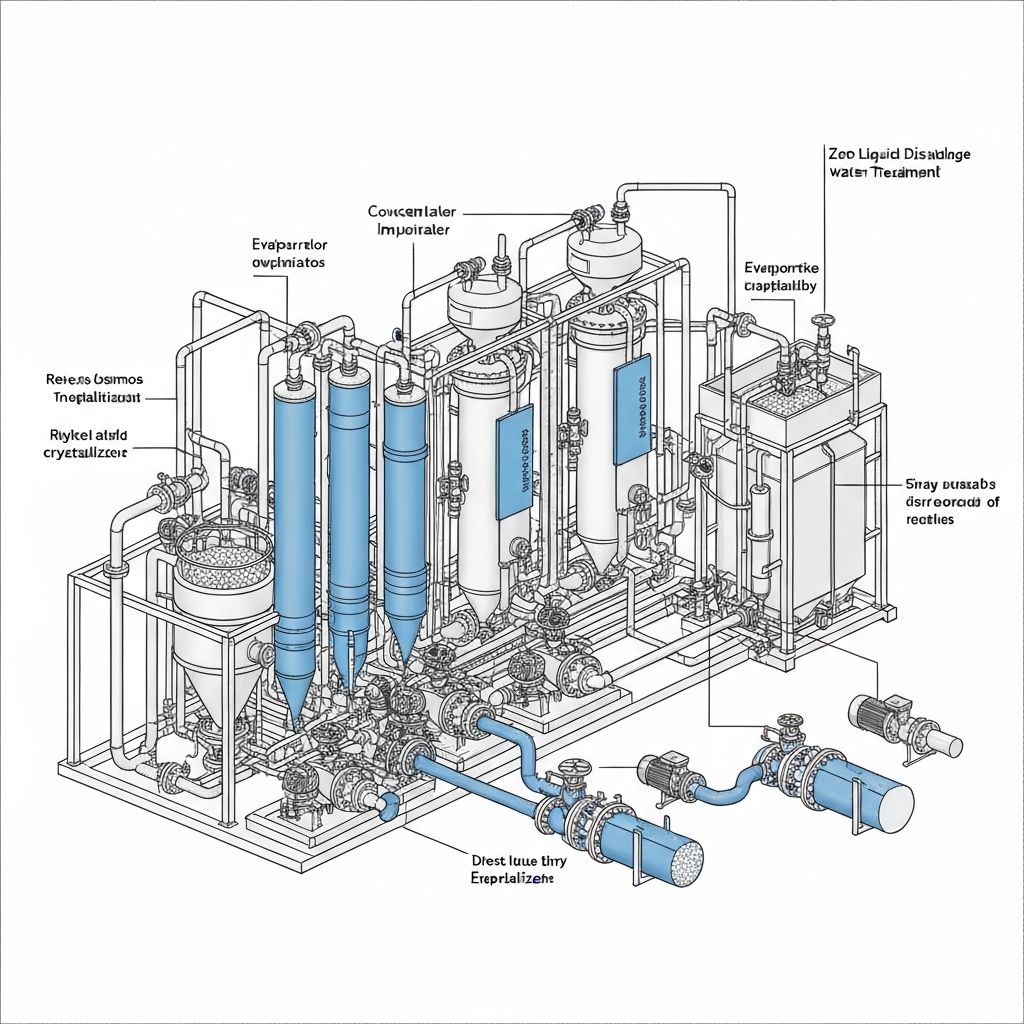

Emerging Technologies

- Electrocoagulation

- Advanced oxidation processes

- Membrane bioreactors

- Zero liquid discharge systems

Conclusion

Effective ETP chemical treatment requires careful selection of chemicals based on wastewater characteristics, treatment objectives, and regulatory requirements. A well-designed chemical treatment program ensures compliance while optimizing operational costs.

ChemParks offers comprehensive ETP chemical solutions customized to your industry and wastewater characteristics. Contact us for detailed analysis and treatment program design.