Membrane Fouling Prevention: Best Practices and Solutions

Discover insights on water treatment solutions and technologies.

Membrane fouling remains one of the most significant challenges in water treatment operations, impacting both performance and operating costs. At ChemParks, we've developed comprehensive strategies to prevent, control, and mitigate fouling across various membrane applications.

Understanding Membrane Fouling

Membrane fouling occurs when suspended solids, colloids, biological materials, or scaling compounds accumulate on membrane surfaces, reducing permeate flux and increasing operational pressure requirements. Understanding the different types of fouling is crucial for implementing effective prevention strategies.

Types of Membrane Fouling

- Particulate Fouling: Deposition of suspended solids and colloids

- Scaling: Inorganic salt precipitation on membrane surfaces

- Biological Fouling: Biofilm formation from microbial growth

- Organic Fouling: Adsorption of natural organic matter and oils

Pretreatment Optimization

Effective pretreatment is the first line of defense against membrane fouling. A well-designed pretreatment system can remove up to 99% of potential foulants before they reach the membranes.

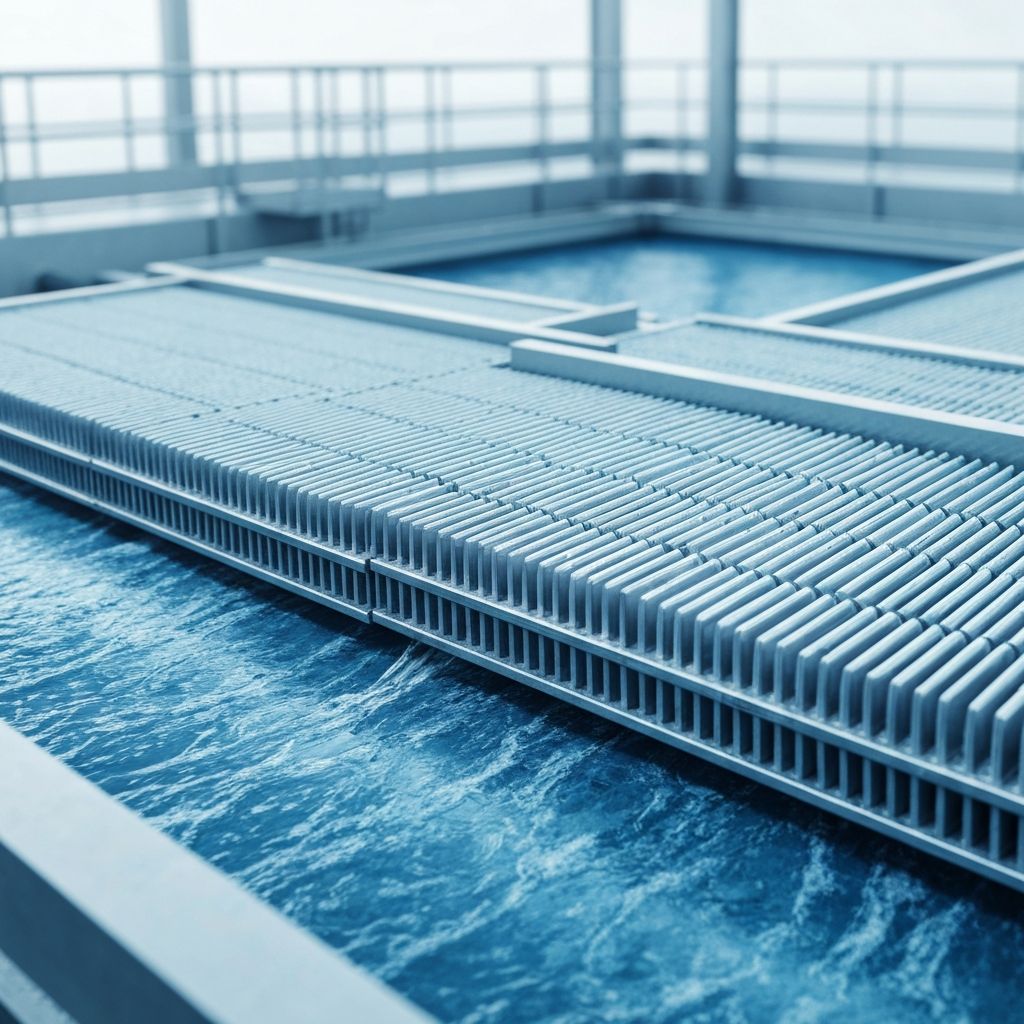

Conventional Pretreatment Technologies

Traditional pretreatment methods remain essential for fouling prevention:

- Multimedia Filtration: Removes particles >10 μm through layered media beds

- Cartridge Filtration: Final barrier for particles 1-5 μm

- Softening: Calcium and magnesium removal to prevent scaling

- Antiscalant Dosing: Chemical inhibition of scale formation

Advanced Pretreatment Solutions

Modern pretreatment technologies offer enhanced fouling prevention:

- Ultrafiltration (UF): Removes suspended solids, colloids, and microorganisms down to 0.02 μm

- Microfiltration (MF): Cost-effective removal of particles 0.1-10 μm

- Dissolved Air Flotation (DAF): Effective for oil, grease, and light particle removal

- Electrocoagulation: Removes colloids and emulsified oils through electrochemical processes

Chemical Treatment Strategies

Strategic chemical dosing can significantly reduce fouling potential when properly implemented.

Antiscalant Selection and Dosing

Choosing the right antiscalant is critical for fouling prevention:

- Phosphate-based Antiscalants: Effective for calcium carbonate and sulfate control

- Polymer-based Antiscalants: Superior dispersion of colloids and silt

- Hybrid Formulations: Multiple mechanisms for comprehensive scale control

- Dosage Optimization: Typically 1-5 ppm based on water chemistry and recovery

Biocides and Disinfectants

Biological fouling prevention requires carefully selected biocides:

- Oxidizing Biocides: Chlorine, chlorine dioxide, and ozone (with membrane compatibility considerations)

- Non-Oxidizing Biocides: DBNPA, glutaraldehyde, and isothiazolinones

- Biofilm Dispersants: Enzymatic cleaners that break down EPS matrix

- Shock Dosing: Periodic high-concentration treatments for established biofilms

Operational Best Practices

Proper operational procedures significantly impact fouling rates and membrane longevity.

Flux and Recovery Management

Operating within optimal flux ranges prevents rapid fouling:

- Design Flux vs. Operating Flux: Maintain 20-30% below maximum design flux

- Progressive Recovery Increases: Gradual recovery optimization during commissioning

- Flux Normalization: Temperature-compensated flux monitoring

- Cross-flow Velocity Optimization: Adequate turbulence for fouling control

Monitoring and Early Detection

Proactive monitoring enables early fouling detection:

- Normalized Permeate Flow: Track flux decline trends

- Salt Rejection Monitoring: Early indicator of membrane damage

- Differential Pressure Tracking: Monitor feed-concentrate pressure drop

- SDI and Turbidity Testing: Regular feed water quality assessment

Cleaning Protocol Optimization

Even with excellent prevention, periodic cleaning is necessary. Optimized cleaning protocols maximize effectiveness while minimizing chemical usage.

Clean-In-Place (CIP) Procedures

Effective CIP programs include multiple cleaning stages:

- Low pH Cleaning: Acid formulations (0.1-0.5% citric acid or HCl) for inorganic scale removal

- High pH Cleaning: Alkaline formulations (0.1-0.5% NaOH) for organic fouling

- Chelating Agents: EDTA-based cleaners for metal oxide removal

- Surfactants: Non-ionic surfactants for oil and grease removal

Cleaning Frequency Optimization

Determining optimal cleaning intervals balances performance and cost:

- Pressure Drop Triggers: Clean when feed-concentrate ΔP increases 15%

- Flux Decline Triggers: Clean when normalized flow drops 10-15%

- Time-based Cleaning: Scheduled cleaning every 3-6 months

- Performance-based Cleaning: Customized triggers based on operating conditions

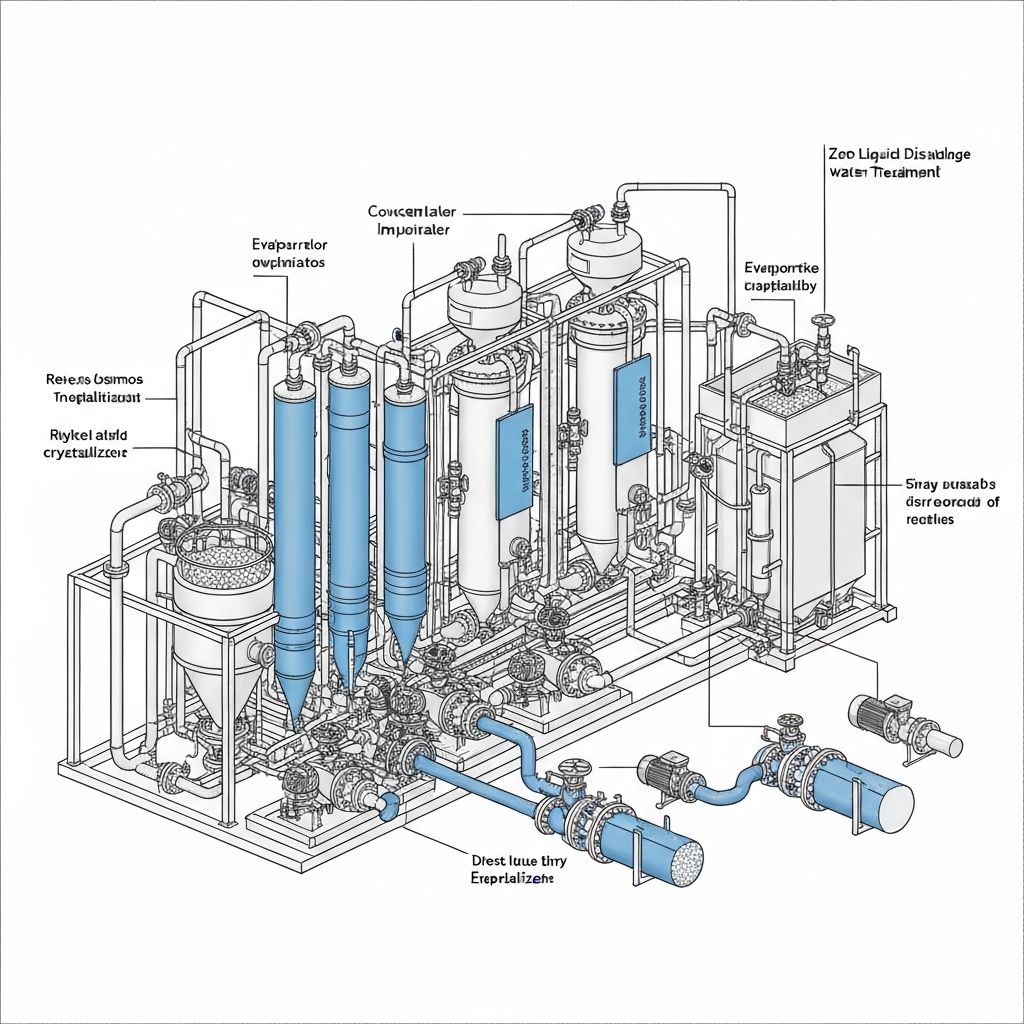

Advanced Fouling Prevention Technologies

Cutting-edge technologies are revolutionizing fouling prevention strategies.

Membrane Surface Modifications

Advanced membrane surface treatments reduce fouling propensity:

- Hydrophilic Coatings: Reduce organic and biological adhesion

- Antimicrobial Surfaces: Silver or copper nanoparticle incorporation

- Smooth Surface Technologies: Reduced roughness limits foulant attachment

- Electrically Conductive Membranes: Apply electrical fields to prevent fouling

Smart Monitoring Systems

IoT-enabled monitoring provides real-time fouling assessment:

- Ultrasonic Monitoring: Real-time cake layer thickness measurement

- Optical Sensors: Direct fouling layer visualization

- AI-driven Predictive Analytics: Fouling prediction and optimization

- Automated Chemical Dosing: Real-time adjustment based on fouling potential

Cost-Benefit Analysis of Fouling Prevention

Investing in comprehensive fouling prevention delivers significant returns:

Direct Cost Savings

- Reduced chemical consumption through optimized dosing

- Lower energy costs from stable operating pressures

- Extended membrane life reducing replacement frequency

- Decreased downtime and maintenance labor costs

Indirect Benefits

- Consistent product quality with stable operation

- Improved plant reliability and uptime

- Reduced environmental impact through chemical optimization

- Enhanced compliance with discharge regulations

Industry-Specific Considerations

Municipal Water Treatment

Municipal systems face unique fouling challenges from natural organic matter and seasonal variations. Effective strategies include:

- Seasonal pretreatment adjustments for algal blooms

- Enhanced coagulation for natural organic matter removal

- Biological activated carbon filters for organic foulant removal

Industrial Applications

Industrial systems must address process-specific foulants:

- Oil and Gas: Hydrocarbon removal and emulsion breaking

- Food and Beverage: Organic load management and sanitization

- Power Generation: Silica and hardness control

- Pharmaceuticals: High-purity requirements and microbial control

Conclusion

Effective membrane fouling prevention requires a comprehensive approach combining proper pretreatment, chemical treatment, operational optimization, and advanced monitoring technologies. By implementing these strategies, facilities can significantly reduce fouling rates, extend membrane life, and optimize operational costs.

ChemParks offers comprehensive fouling prevention solutions tailored to your specific application. Contact us to develop a customized strategy for your membrane systems.